Steam turbine-part-1-Steam turbine parts-How does a steam turbine work?

Steam Turbine

How does a steam turbine work?

ans: In simple terms, a rotary engine works by using a heat offer (gas, coal, nuclear, solar) to heat water to terribly high temperatures until it's converted into steam. As that steam flows past a turbine's spinning blades, the steam expands and cools.

Steam turbine is one of the most

important prime mover for generating electricity. This falls der the category

of power producing turbo-machines. In the turbine, the energy level of the

working

coes on decreasing along the flow

stream. Single unit of steam turbine can develop power ranging I mW to

1000 mW. In general, 1 mW, 2.5 mW, 5 mW, 10 mW, 30 mW, 120 mW, 210 mW, 250 mW,

350 mW, 500 mW, 660 mW, 1000 mW are in common use. The thermal efficiency of

modern steam power plant above 120 mW is as high as 38% to 40%.

The purpose

of turbine technology is to extract the maximum quantity of energy from the

working fluid, to convert it into useful work with maximum efficiency, by means

of a plant having maximum reliability, minimum cost, minimum supervision and

minimum starting time. This chapter deals with the types and working of various

types of steam turbine.

PRINCIPLE OF

OPERATION OF STEAM TURBINE

The principle

of operation of steam turbine is entirely different from the steam engine. In

reciprocating steam engine, the pressure energy of steam is used to overcome

external resistance and the dynamic action of steam is negligibly small. But

the steam turbine depends completely upon the dynamic action of the steam.

According to Newton's Second Law of Motion, the force is proportional to se

rate of change of momentum (mass x velocity). If the rate of change of momentum

is caused in the

Cam by allowing a high velocity jet of

steam to pass over curved blade, the steam will impart a force to w blade. If

the blade is free, it will move off (rotate) in the direction of force. In

other words, the motive a steam turbine is obtained by the rate of

change in moment of momentum of a high velocity jet am impinging on a curved

blade which is free to rotate. The steam from the boiler is expanded in s or

nozzle where due to fall in pressure of steam, thermal energy of steam is

converted into energy of steam, resulting in the emission of a high velocity

jet of steam which, Principle of - impinges on the moving vanes or blades of

turbine.

ached on a

rotor which is mounted on a shaft supported on bearings, and here steam underage

in direction of motion due to curvature of blades which gives rise to a change

in momentum and therefore a force. This constitutes the driving force of

the turbine. This arrangement is It should be realized that the blade obtains

no motive force from the static pressure of the steam or any impact of the jet,

because the blade in designed such that the steam jet will glide on and off the

hi without any tendency to strike it.

when the blade is

locked the jet enters and leaves with equal velocity thus develops maximum

force if we neglect friction in the blades. Since the blade velocity is zero

mechanical work is done. As the blade is allowed to speed up, the leaving

velocity of jet from the blade reduces, which reduces the force. Due to blade

velocity the work will be done and maximum work done when the blade speed is

just half of the steam speed. In this case, the steam velocity from the blade

is near about zero i.e. it is trail of inert steam since all the kinetic energy

of steam is converted into work The force and work done become zero when the

blade speed is equal to the steam speed. From the above discussion, it follows

that a steam turbine should have a row of nozzles, a row of moving blades fixed

to the rotor, and the casing (cylinder). A row of nozzles and a raw of moving

blades constitute a stage of turbine.

CLASSIFICATION OF STEAM TURBINE

Steam turbine may be classified as

follows:

(A) On the

Basis of Principle of Operation:

(i) Impulse

turbine (a) Simple, (b) Velocity stage, (c) Pressure stage, (d) combination of

(b) and (c)

(ii)

Impulse-reaction turbine (a) 50% (Parson's) reaction, (b) Combination of impulse

and reaction.

Impulse Turbine: If the flow of steam through the nozzles

and moving blades of a turbine takes place in such a manner that the steam is

expanded only in nozzles and pressure at the outlet side the blades is equal to

that at inlet side; such a turbine is termed as impulse turbine because it

works on the principle of impulse. In other words, in impulse turbine, the drop

in pressure of steam takes place only in nozzles and not in moving blades. This

is obtained by making the blade passage of constant cross-section area

As a general

statement it may be stated that energy transformation takes place only in

nozzles and O moving blades (rotor) only cause energy transfer. Since the rotor

blade passages do not cause any nacelles elation of fluid, hence chances of

flow separation are greater which results in lower stage efficiency.

(i) Impulse-Reaction Turbine: In this turbine, the drop in

pressure of steam takes place in fixed (nozzles) as well as moving blades. The

pressure drop suffered by steam while passing through the Moving blades

causes a further generation of kinetic energy within the moving blades, giving

rise to reaction and adds to the propelling force which is applied through the

rotor to the turbine shaft. Since this turbine works on the principle of

impulse and reaction both, so it is called impulse-reaction turbine. This is

achieved by making the blade passage of varying cross-sectional area

(converging type).

In general,

it may be stated that energy transformation occurs in both fixed and moving

blades. The rotor blades cause both energy transfer and transformation. Since

there is an acceleration of flow in moving blade passage hence chances of

separation of flow is less which results in higher stage efficiency.

(B) On the basis of "Direction of

Flow": (i) Axial flow

turbine, (ii) Radial flow turbine, (iii) Tangential flow turbine.

(1) Axial Flow Turbine. In axial flow turbine, the steam flows along

the axis of the shaft. It is the most suitable turbine for large

turbo-generators and that is why it is used in all modem steam power plants.

(i) Radial Flow Turbine. In this turbine, the steam flows in the radial

direction. It incorporates two shafts end to end, each driving a separate

generator. A disc is fixed to each shaft. Rings of 50% reaction radial-flow

bladings are fixed to each disk. The two sets of bladings rotate counter to

each other. In this way, a relative speed of twice the running speed is

achieved and every blade row is made to work. The final stages may be of axial

flow design in order to achieve a larger area of flow. Since this type of

turbine can be warmed and started quickly, so it is very suitable for use at

times of peak load. Though this type of turbine is very successful in the

smaller sizes but formidable design difficulties have hindered the development

of large turbines of this type. In Sweden, however, composite radial/axial Tlow

turbines have been built of outputs upto 275 MW. Sometimes, this type of

turbine is also known as Lungstrom turbine after the name of its inventor B and

F. Liungstrom of Sweden.

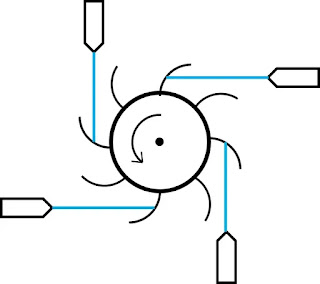

(iii) Tangential Flow Turbine. In this type, the steam flows in

the tangential direction. This turbine is very robust but not particularly

efficient machine, sometimes used for driving power station auxiliaries. In

this turbine, nozzle directs steam tangentially into buckets milled in the

periphery of a Single wheel, and on exit the steam turns

through a

reversing chamber, reentering bucket further round the periphery. This process

is repeated several times, the steam flowing a helical path. Several nozzles

with reversing chambers may be used around the wheel periphery.

(C) On the Basis of Means of Heat

Supply: (1) Single pressure turbine, (i) Mixed or dual

pressure turbine (ii) Reheated turbine. (a) Single (b) Double (i) Single Pressure

Turbine : In this type of turbine, there is single source of steam supply

(i) Mixed or Dual Pressure Turbine : This type of turbines, use two sources of

steam, at different pressures. The dual pressure turbine is found in nuclear

power stations where it uses both sources continuously. The mixed pressure

turbine is found in industrial plants (eg, rolling mill. colliery, etc.) where

there are two supplies of steam and use of one supply is more economical than

the other, for example, the economical steam may be the exhaust steam from

engine which can be utilized in the L. P. stages of steam turbine. Dual

pressure system is also used in combined cycle.

(iii) Reheated Turbine : During its passage through the turbine

steam may be taken out to be reheated in a reheated incorporated in the boiler

and returned at higher tempera-true to be expanded in (Fig. 6,6). This is done

to avoid erosion and corrosion problems in the bladings and to improve the

power output and efficiency. The reheating may be single or double or triple.

(D) On the Basis of Means of Heat

Rejection :

(1) Pass-out or extraction turbine,

(in) Regenerative turbine, (iii) Condensing turbine, (iv) Non condensing

turbine, (v) Back pressure or topping turbine.

(i) Pass-out Turbine. In this turbine, (Fig. 6.4), a

considerable proportion of the steam is ex traced from some suitable point in

the turbine where the pressure is sufficient for use in process heating: the

remainder continuing through the turbine. The latter is controlled by separate

valve-gear to meet the

difference

between the pass-out steam and electrical load requirements. This type of

turbine 15 there is

dual demand of steam-one for power and the other for industrial heating, for

exam car industries. Double pass-out turbines are sometimes used.

G)

Regenerative Turbine. This

turbine incorporates a number of extraction branches, through ob small

proportions of the steam are continuously extracted for the purpose of heating

the bon Goed water in a feed heater in order to increase the thermal efficiency

of the plant. Now a days, all steam power plants are equipped with reheating

and regenerative arrangement.

(iii) Condensing Turbine. In this turbine, the exhaust steam is

condensed in a condenser and the condensate is used as feed water in the boiler.

By this way the condensing turbine allows the steam to expand to the lowest

possible pressure before being condensed. All steam power plants use this type

of turbine.

(iv) Non-Condensing Turbine. When the exhaust steam coming out from the

turbine is not condensed but exhausted in the atmosphere is called

non-condensing turbine. The exhaust steam is not recovered for feed water in

the boiler.

(v) Back Pressure or Topping Turbine. This type of turbine rejects the

steam after expansion to the lowest suitable possible pressure at which it is

used for heating purpose. Thus back pressure turbine supplies power as well as

heat energy.

The back pressure turbine generally

used in sugar industries provides low pressure steam for heating apparatus,

where as a topping turbine exhausts into a turbine designed for lower steam

conditions.

(E) On the Basis of Number of Cylinder:

Turbine may be classified as (i) Single cylinder and (ii) Multi-cylinder.

(i) Single Cylinder. When all stages of turbine are housed in one

casing, then it is called single cylinder. Such a single cylinder turbine uses

one shaft.

(ii) Multi-Cylinder. In large output turbine, the

number of the stages needed becomes so high that additional bearings are

required to support the shaft. Under this circumstances, multi-cylinders are

used.

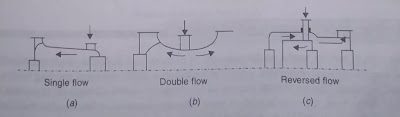

(F) On the Basis of Arrangement of

Cylinder Based on General Flow of Steam. (i) Single flow, (ü) Double flow, and

(iii) Reversed flow

Single Flow. In a single flow turbines,

the steam enters at one end, flows once [Fig. 6.5(a)] through

The ladings in a direction approximately parallel to this axis, emerges at the other end. High pressure cylinder uses single flow. This is also common in small turbines.I uses

single flow. This is also common in small turbines.

Double Flow. In this type of turbines, the steam enters at

the center and divides, the two portions passing axially away from other

through separate sets of balding on the same rotor Fig. 6.5(b). The low

Pressure

cylinder normally uses double flow). This type of unit is completely balanced

against thrust and gives large area of flow through two sets of beading. This

also helps in reducing the height as mass flow rate becomes half as compared to

single flow for the same conditions,

Reversed Flow. Reversed flow arrangement is

sometimes used in h.p, cylinder where : temperature steam is used on the larger

sets in order to minimize differential expansion i.e. expansion of rotor and

casing. The use of single, double and reversed flow .

(G) On the Basis of Number of Shaft ()

Tandem compound, (ii) Cross compound

(1) Tandem Compound. Most multi-cylinder turbines drive a

single shaft and single generate Such turbines are termed as tandem compound

turbines.

(ii) Cross Compound. In this type, two shafts are used

driving separate generator. The may be one of turbine house arrangement,

limited generator size, or a desire to run shafting at half speed. The latter

choice is sometimes preferred so that for the same centrifugal stress, longer

blades may be used giving a larger leaving area, a smaller velocity and hence a

small leaving loss.

(H) On the Basis of Rotational Speed

(i) constant speed turbines (ii) Variable speed turbines

(1) Constant Speed Turbines. Requirements of rotational speed are

extremely rigid in turbines which are directly connected to electric generators

as these must be a-c unit except in the smallest sizes and must therefore run

at speeds corresponding to the standard number of cycles per second and

governed by the following equation :

N= 120 x Number of cycles per second = 120 f/p

Number of poles

The minimum number of poles, in a

generator is two and correspondingly the maximum possible speed for 60 cycle is

3,600 rpm; for 50 c/s of frequency, the speeds would be 3,000, 1500 and 750 rpm

for 2.4 and 8 poles machines respectively.

(in) Variable Speed Turbines. These turbines have geared units and may have

practically any speed ratio between the turbine and the driven machine so that

the turbine may be designed for its own most efficient speed. Such turbines are

used to drive ships, compressors, blowers and variable frequency generators,

THE SIMPLE IMPULSE TURBINE

This type of

turbine works on the principle of impulse and is shown diagrammatically. It

mainly consists of a nozzle or a set of nozzles, a rotor mounted on a shaft,

one set of moving blades attached to the rotor and a casing. The uppermost

portion of the diagram shows a longitudinal section through the upper half of

the turbine, the middle portion shows the development of the nozzles and balding

i.e. the actual shape of the nozzle and balding, and the bottom portion shows

the variation of absolute velocity and absolute pressure during flow of steam

through passage of nozzles and blades. The example of this type of turbine is

the de-Laval Turbine,

It is obvious from the figure that the

complete expansion of steam from the steam chest pressure to the exhaust

pressure or condenser pressure takes place only in one set of nozzles i.e. the

pressure drop takes place only in nozzles. It is assumed that the pressure in

the recess between nozzles and blades

remains the

same . The steam at condenser pressure or exhaust pressure enters the bald and comes out same pressure i.e. the pressure of steam in the blade passages

remains approximately cons Juan to the condenser pressure. Generally,

converging-diverging nozzles are used. Due to the relatively

ratio of

expansion of steam in the nozzles, the steam leaves the nozzles at a very high per

sonic), of about 1100 m/s. It is assumed that the velocity remains constant in

the recess between

sees and the blades. The steam at such

a high velocity enters the blades and reduces along the Ce of blades and comes

out with an appreciable amount of velocity (Fig. 6.6).

As it has been already shown, that for

the good economy or maximum work, the blade seeded should be one half of the

steam speed so blade velocity is of about 500 m/s which is very en high. This

results in a very high rotational speed, reaching 30,000 r.p.m. Such high

rotational speeds can only be utilized to drive generators or machines with

large reduction gearing arrangements.

In this

turbine, the leaving velocity of steam is also quite appreciable resulting in

an energy loss, called "carry over loss" or "leaving velocity

loss”. This leaving loss is so high that it may amount to about 11 percent of

the initial kinetic energy. This type of turbine is generally employed where

relatively small power is needed and where the rotor diameter is kept fairly

small.

COMPOUNDING OF IMPULSE TURBINE

Compounding

is a method for reducing the rotational speed of the impulse turbine to

practical limits. As we have seen, if the high velocity of steam is allowed to

flow through one row of moving blades, it produces a rotor speed of about 30,000

r.p.m. which is too high for practical use. Not only this,

the leaving

loss is also very high. It is therefore essential to incorporate some

improvements simple impulse turbine for practical use and also to achieve high

performance. This is possible by ing use of more than one set of nozzles,

blades, rotors, in a series, keyed to a common shaft, so the the steam pressure

or the jet velocity is absorbed by the turbine in stages. The leaving loss also

will be less. This process is called compounding of steam turbines. There are

three main types

(a) Pressure-compounded impulse

turbine.

(b)

Velocity-compounded impulse turbine.

(c) Pressure

and velocity compounded impulse turbine.

PRESSURE

COMPOUNDED IMPULSE TURBINE

In this type

of turbine, the compounding is done for pressure of steam only i e. to reduce

the high rotational speed of turbine the whole expansion of steam is arranged

in a number of steps by employing a number of simple turbine in a series keyed

on the same shaft as shown. Each of these simple impulse turbine consisting of

one set of nozzles and one row of moving blades is

set of nozzles and one row of moving

blades is known as a stage of the turbine and thus this turbine consists of

several stages. The exhaust from each row of moving blades enters the

succeeding set of nozzles. Thus we can say that this arrangement is nothing but

splitting up the whole pressure drop (Fig. 6.7).

from the

steam chest pressure to the condenser pressure into a series of smaller

pressure drop across several stages of impulse turbine and hence this turbine

is culled, pressure-compound impulse turbine.

The pressure and velocity variation are

also shown. The nozzles are fitted into a diaphragm which is locked in the

casing. This diaphragm separates one wheel chamber from another. All rotors are

mounated on

the same shaft and the blades are attached on the rotor. The rotor (i.e. disc)

may be keyed shaft or it may be integral part of shaft. The expansion of steam

only takes place in the nozzles while pressure remains constant m

ins constant in the

e ING blades because each stage is a

simple impulse turbine. So it is obvious from the pressure curve

race between any two consecutive

diaphragms is filled with steam at constant pressure and - either side of the

diaphragm is different. Since the diaphragm is a stationary part, there is

trance between the rotating shaft and the diaphragm. The steam tends to leak

through this cecal for which devices like labyrinth packing, etc. are used.

Since the drop in pressure of steam per

stage is reduced, so the steam velocity leaving the nozzles Monte-ring the

moving blades is reduced which reduces the blade velocity. Hence for good

economy of

um work shaft speed is significantly

reduced so as be reduced by increasing the number of stages

ding to ones need. The leaving velocity

of the last stage of the turbine is much less compared to the DE Laval turbine

and the leaving loss amounts to about 1 to 2 percent of the initial total

available energy. This turbine was invented by the late prof L. Gateau and so

it is also known as Gateau Turbine.

I would suggest must go for best electrician. we provide Electrical Repair Springfield Mo at affordable prices. for more info visit our website.

ReplyDelete