Electrical Earthing - types of earthing - Methods and Types of Earthing & Grounding

Electrical Earthing ,types of earthing

PLATE

EARTHING

Describe one method of providing good earth for an electric substation.

Ans. For good earth in electric substation, plate earthling Is used. Plate earthling: In plate earthling, the looping earth wire is bolted effectively with the earth plate made up of copper size 60 cm x 60 cm x 3.18 mm (2' 2' x 1/4") and embedded 3 meters in ground. Copper plates are found to be most effective earth electrodes and are not affected by the soil moisture i.e., these do not get rusted. But on account of its high material cost, galvanized iron plates are preferred and usually used for normal work.

In case the soil restive is high, the plate should be placed vertically in ground at a higher depth. A line diagram showing the plate earthling system is shown. The plate is kept with its face vertical and is so arranged that it is embedded in an alternate layer of coke and salt for a minimum thickness of about 15 cm.

The coke salt decreases the earth resistance. It should be remembered that the nuts and bolts must be of copper for copper plate and should be of G.I. for G.I. plates. Usually, the earth wire is drawn through a G.I. pipe fitted with a tunnel on the top through which salty water is poured in the pit of earth plate from time to time in summer season when the moisture of the soil will decrease to a larger extent which will increase the earth resistance.

The conductivity,

i.e., earthling efficiency, increases with the increase of plate area and depth

of embedding. Its only disadvantage is that discontinuity of earth wire and

plate below the earth cannot be observed physically; hence is misleading and

sometimes results in heavy loss in case of any fault.

PIPE

EARTHING

Which type of earthing is mostly used?

ans:- pipe earthing is mostly used

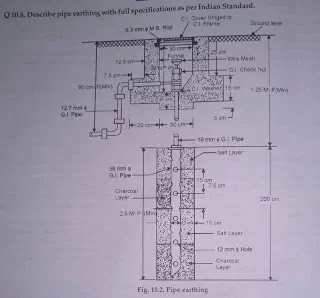

Describe the

pipe earthling with full specification as per Indian standard.

Ans. Pipe earthling In this system of earthling a G.I. pipe of 38 mm die and 2 meters (7 feet) length is embedded vertically in ground to work as earth electrode but the depth depends upon the soil conditions; there is no hard and fast rule for this. The earth wires are fastened to the top section of the pipe with nut bolts. The pit area around the G.I. pipes is filled with salt and coal mixture for improving the soil condition and efficiency of the earthling system.

The contact surface area of G.L pipe with soil is more in comparison to the plate because of its circular section and hence can take up heavy leakage current for the same electrode size. The earth wire connection with the G.I. pipe being above the ground level can be checked for carrying out continuity tests as and when desired while in plate earthling it is difficult - It is an advantage over the plate earthling IT IS DIFFICULT – It is an advantage over the plate earthling.

IMPROVING

OF EARTH RESISTANCE

What should be the resistance of a good earth? If it increases, what steps should be taken to reduce it? How the earth resistance is measured?

Ans. The earth resistance for copper wire is 112 and for G.I. wire it should not be more than 3 ohm. Earth resistance is measured by earth tester which is explained in chapter Electrical Instruments. As the total current is to pass through the earth wire, the earth resistance should be kept as low as possible. The resistance increases in hot days (summer days).

To Reduce Earth Resistance

By pouring water:

The dampness of the soil and coal salt paste depends upon the atmospheric conditions. In summer season fresh salt water should be poured through the pipe over the coal bed. The soil resistance can be lowered only to a certain limit by the above method, and in order to lower it further following is the additional steps to be taken

(a) Increase in plate area :

In case of increase in plate area, the decrease of resistance value is not in direct proportion to the area. It is found that to reduce the resistance value by one-sixth, the increase in area is 36 times more for the same soil condition and depth of electrode. So this method is not used.

(b) Increase in depth:

The increase of depth below the ground level of the same plate reduces the resistivity of the earthling system. It is found that plate area reduces to fifty percent when the depth is doubled for the soil resistance. With this method also the soil resistance value cannot be lowered as much as desired on account of excavation work; however, it helps to a great extent.

2. Electrodes in parallel:

In this system of lowering earth resistance, the soil resistance falls considerably as the number of electrodes interconnected in parallel are increased for same depth. This method is suitable only where greater area of free oil is available for earthling. The plant should be so placed in parallel as not to overlap the earthling region covered by the individual electrode. R1 and R2, etc., are the earth resistance of each electrode and are the total earth resistance of the system.

No comments:

if you have any doubts,please let me know